Everybody knows Henry, the famous Red and Black Vacuum Cleaner, with the smiley face, which often end up tipping over or getting stuck in doors. 😂

Henry – The Almost Indestructible Tub Vac – with a Cheeky Smile:)

These little Vacuum Cleaners were invented by Chris Duncan, MBE, who launched Numatic in 1969, having seen a need for a rugged and reliable cleaner to clean the inside of boilers.

At a trade show in the mid-1970s, founder Chris Duncan and a salesman dressed up one of their commercial machines with ribbon, a Union Jack badge, and a hat, then drew a pair of eyes and a crude smile on the bucket. The next day, visitors noticed it and laughed; Duncan then decided to ask his advertising team to design a proper ‘face’, which would become a staple of Numatic’s range, making their products easily identifiable from their competitors’. This is where the smiley face comes from:)

In 1981 Henry became the first Numatic International model to have a name on its lid, which had become to look like a Bowler hat, replacing the ‘Numatic’ brand logo. Henry was also one of the first vacuums to use large-capacity microfibre dust bags known as HEPA-FLO bags, made of a material that retains dust and is stronger than the paper usually used, which can tear.

Henrys were originally manufactured in Bedminster, Dorset, until Numatic moved production in 1990 to Chard, Somerset.

Henry gas become a household name, with millions sold world wide. He also has a wide selection of Brothers and Sisters. (James, Hetty, Charles and George, to name a few) These little hoovers come in all shapes and sizes, and some can up up liquids as well as solids. If you want a decent little Tub Vac, I recommend getting a Henry. (Or one of his Siblings)

Henry has a cult following and even has his own Fan Club on Facebook, which I am a member of.

Regular Henry Maintenance

Maintaining your Henry is a important job, as it will help prolong his life and make cleaning easier. A Henry that is shown a little love and is well looked after, should give you years and years of faithful service.

I know someone who has a Henry from 1992, which is still on it’s original motor and is going strong to this day!

Here are my top tips for keeping your Henry working properly:

Think Health and Safety: Always switch off your Henry at the power button after every use and remove the plug from the wall, rewinding \ wrapping the cable round the hat (Depending on your model) when not in use.

You should always switch off and unplug your Henry, when maintaining it.

Important Checks: Cable and Plug

You should check the plug for damage, each time you use your Tub Vac. Make sure the pins are not damaged and that the sealed plug itself isn’t damaged. You should also check the cable, making sure the insulation is not damaged. DO NOT USE, If the cable or plug is damaged. You should also make sure that the cable rewind is working, if your machine has one.

Empty The Bag Regularly

Changing \ emptying the bag, will help to keep good suction on your Henry. I empty the dust bag, when it is 3 quarters full. I prefer to use Microfibre Bags, as they can be reused.

You will need to unclip and lift off Henry’s Hat, to access the dustbag. The filter lives on top of the bag, so you will need to remove this too. To empty the bag, wear a dust mask and bang it against the inside of the wheelie bin. Once a month, wash the bag in warm water with a little detergent and hang it to dry, replacing it with another microfibre bag, while the wet one dries. If you use paper bags, replace it, when it is a third full and dispose of the old bag.

How to Put Henry’s Hat Back On

Getting the hat back on Henry can be quite tricky. You need to make sure that the word Henry, is aligned with the nozzle of the hose. This means making sure that the word Henry, is right at the front. Make sure also the filter is in properly, or the hat will not go on. Then it is a simple case of clipping the hat down, by pushing in the securing clips and away you go!

Clean the Head

It is a good idea to remove the head of your Henry and give it a clean. A blocked head will not suck up anything, so it is a good idea to give it a clean every week.

If it is stuck and won’t come off the pole, do not panic! Either:

- Hold the pole in one hand and place both feet on the head. Using your weight, press down and twist the poles. The poles should release easily. If they are being stubborn, use WD40 or a drop of Washing Up Liquid, to lubricate the pole.

- Put the head and pole in the sink and pour boiling hot water on it. Twist and the pole should be able to be puled free.

The best way to clear any dust from the head, is to use a wire bottle brush. Use this to clear any bits of dust and other debris. It is a good idea to use a cleaning wipe, to clean the exterior of the head as well.

Clean the Poles

The poles can also easily get blocked and prevent good suction. I use a broom handle to clear blockages in the poles, once I have separated them. This will push any debris out the poles. I wipe my poles once a week with a cleaning wipe.

If your hose is blocked, you can use the same method. However, slowly ease the broom handle up the pole, pulling it over slowly. This will push any debris out.

Give your poles a good wipe with a good quality Chrome Cleaner. I suggest using Bar Keeper’s Friend.

Clean The Filters

I clean my filters once a week. This involves removing Henry’s hat. Thankfully this just unclips and lifts off. Remove the filter and take it outside. Bang it against the wall, to release any debris. Put the filter back on, (making sure it goes in the right way) then replace Henry’s hat. This only goes on one way and should have the word Henry, aligned right above the eyes on the tub. Clip the hat back on and test that it is secure, by trying to lift him with the handle.

I clean my filters once a week. This involves removing Henry’s hat. Thankfully this just unclips and lifts off. Remove the filter and take it outside. Bang it against the wall, to release any debris. Put the filter back on, (making sure it goes in the right way) then replace Henry’s hat. This only goes on one way and should have the word Henry, aligned right above the eyes on the tub. Clip the hat back on and test that it is secure, by trying to lift him with the handle.

Clean the Wheels

The wheels often get forgotten and over time, can get gunked up, which will stop Henry from moving across the floor. To clean the wheels, spray them with WD40 once a week and use a old toothbrush, to remove the build up of gunk. Then give a wipe with Disinfectant, sprayed on a Micro Fibre Cloth.

Wash out the Tub (The Bit The Dust Bag Goes In)

I wash out the tub on a weekly basis. I know he has a dustbag in, but still the tub does easily get dirty.

Think Health and Safety: Always make sure the tub is fully dry, before reassembling! Do not get the hat wet, as you will risk damaging Henry and possibly electrocuting yourself in the process!

First, unscrew the hose and place aside. Then unclip and remove Henry’s Hat. Then take out the filter and place aside. I put him in the sink for this and only fill him with 3 500ml jugs of warm water. This is around 1 1/2 litres. Do not overfill, as the water will come out the hole where the hose connects to.

Add a capful of your favourite disinfectant (Do not use Bleach) and then use a cloth to gently wash the inside of the tub. If it is really dirty, you can use a brush for deeper cleaning. Once done, carefully top the water down the sink. To dry your Henry, you can either use Blue Paper Roll and thoroughly wipe the inside, removing all moisture.

If you can afford more time, you can place Henry’s tub upside down on Blue Paper Roll and leave it to air dry. Once fully dry, reassemble your Henry and he is good to go!

Wash your Tools (Crevice Tool, Furniture Brush, Dusting Tool)

Your Henry Tools also should get a weekly clean. Over time, these will get rather dirty, especially the brushes. I wash mine in the sink, with mild detergent and then hang them up to dry, before putting them back on their caddies. To get the crud out the brushes, use a old comb, to brush out the debris. Quite often, hair and other debris, will get stuck in the brushes, which is a magnet for bacteria and also can clog your Henry up. The same goes for if you have a Henry with the air driven brush. However normally the air powered brush has a removable roller bar, which makes cleaning easier.

While you are at it, visually inspect your tools, to make sure there are no cracks or breakages.

Wipe down your Machine

I wipe down my Henry after every use. I usually spray my Disinfectant on a Micro Fibre Cloth and give him a good rub down. This keeps my Henry looking his best. Remember to also do underneath the handle and bottom of the tub, as these are often places that are overlooked.

For the air holes, I use a can of compressed air, as it gets into the grooves and releases any gunk that may be stuck there. It may also be a good idea to use a cleaning wipe to give the power cord and the plug a wipe once a week as well.

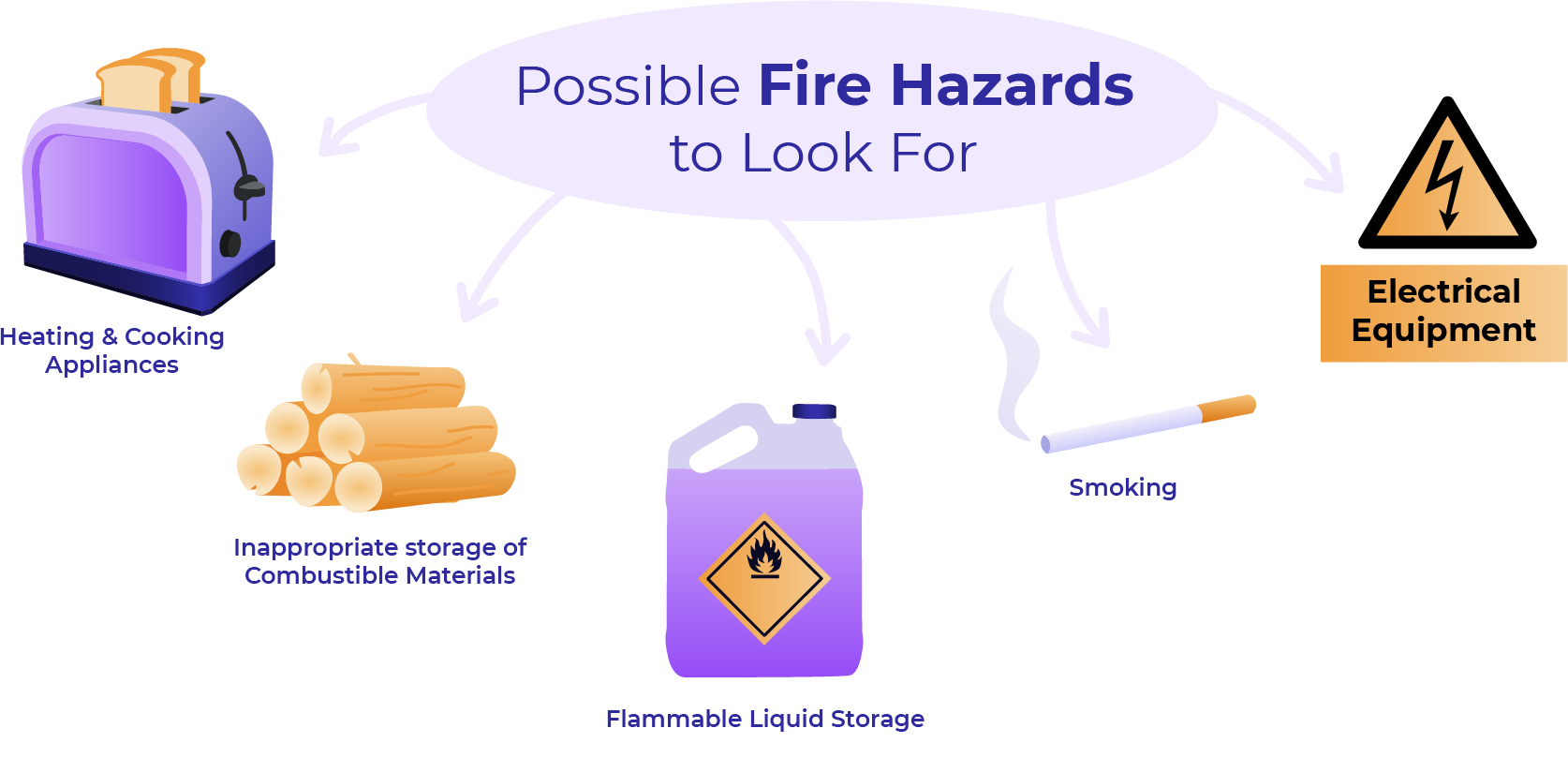

For cleaning the vents on the underside motor casing, I once again used a good old can of compressed air. It is safe, as there is no liquids involved and it will allow you to get any trapped dust out, which can cause your Henry to overheat. A overheated Henry will eventually cut out (as it has a thermal overheat cut off on the motor) or in the worse case scenario, could ultimately catch fire!

So make sure cleaning the underside motor vents is part of your weekly Henry Maintenance.

Check Your Hoses For Splits

Make sure your hoses are intact. A break in the hose can cause complete loss of suction, as the air will escape through the breakage. You can temporally use Gaffer or Duct Tape to seal the breakage, but I do not recommend this, as it may not fix the problem. The best solution, is to order a new hose, from My Henry. (See Below)

Replace Parts When Worn Out

If you need spare poles, accessories or a new machine, visit My Henry, which is your one stop shop for everything Henry Hoover!

Store Your Henry Properly When Not In Use

I make sure that both my Henry Tub Vacs are stowed properly when not in use. This means putting the pole and brush on the hook, on the back of the machine and putting his tools nearly back on their holders on the back of the machine. This helps to make sure Henry is ready for his next cleaning task. Both my Henry Tub Vacs, live against the wall in the cleaning store, when not in use. This makes both machines quickly accessible, when needed.

Bonus Tip: Stopping Your Henry From Tipping Over

It’s a problem any Henry Owner faces… Your Henry tipping over when you drag it along. However, there is a solution. (WEIGH IT DOWN!)

To do this, we have a couple of options:

Method One: Silicone Sands

The 1st solution is a bit messy, but rather fun.

What you need is a bag of sand. I suggest Rainbow Eco Sand from Amazon, as you do not need alot and this should be more than enough for what you need. Then you will need Silicone Resin. You can also get this from good old Amazon.

Now to weigh down your Henry…

- Tip a small amount of sand into the tub of your henry. You only need around 2 inches of sand, which needs to be a level layer.

- Mix the Resin and pour it over the sand, making sure you evenly coat it

- Wait 24 hours for the Resin to dry, before reassembling

Method Two: Dumb Weights

The 2nd solution, is to put a fitness weight at the bottom of the tub. This is a good method to use, if you are unable to use the method above. This method is a little less invasive, but will still make the tub heavy enough, so it won’t fall over. Compared with the 1st method, this will make your Henry quite a bit heaver. So beware of this, when deciding which option to take.

Final Thoughts

A well looked after Henry, will help your carpets look fantastic. Here is a picture of our Stock Room, after I maintained my machine. It looks fantastic. However, you might notice the white marks on the carpet. This is from the Shake N’ Vac I used to make the carpets smell nice. The white marks will fade, as they are caused by people walking over the shake and vac, before I had a chance to suck it up.

However, this will dissipate quite quickly and won’t stain the carpet. (Kath would be on my case if it did that and I don’t want that!!!!!)

Your Vacuum Cleaner is one of the most important tools, in your arsenal of cleaning equipment. Tub Vacs, come in all shapes and sizes, from the Numatic International range of tub vacs, (Henry, Hetty, George etc) to machines that can do wet and dry, shampooing and machines specialising in picking up hazardous materials.

Your Vacuum Cleaner is one of the most important tools, in your arsenal of cleaning equipment. Tub Vacs, come in all shapes and sizes, from the Numatic International range of tub vacs, (Henry, Hetty, George etc) to machines that can do wet and dry, shampooing and machines specialising in picking up hazardous materials.